5S & Visual Management

Should organised work place be a priority?

5S is a workplace organization method that uses a list of five Japanese words SEIRI (Sort), SEITON (Set in Order), SEISO (Shine), SEIKETSU (Standardize), and SHITSUKE (Sustain).

5S is a set of tools & techniques of organizing and managing the workspace and one of the most important Lean Manufacturing Tools. It enables the business to be well organized, clean, uncluttered, and safe by reducing lean wastes by removing unwanted material, identifying and storing the items at right place, maintaining the area and items clean, and sustaining the new order. It’s designed to help build a quality work environment, both physically and mentally, and enhance efficiency and effectiveness making business more profitable by improving productivity, quality, safety and employees morale, it forms a solid foundation upon which to build continuous improvement.

We are leader in Lean,5S and kaizen training, have trained more than 500+ corporate companies and done 100+ implementations ,having expertise in conducting high quality, interactive & result oriented training programs

Our team is made of experienced & passionate trainers & experienced project managers with highly industrial experience, our team work hand-in-hand with your team to help organizations grow & improve their processes drastically, and our training programs areis based on a practical approach so that the participants can fully implement the methodologies taught in real-time projects.

Topics Covered:5S & Visual Management

- 5S Definition

- Unorganised & organised work place examples.

- Unorganised work place-how it affects us?

- Why use 5S?

- 5S overview.

- Examples of each “S”.

- How to implement 5S

- Awareness on lean wastes.

- Why employees don’t maintain 5S, behavioural aspect?

- Creating a culture for change.

- Consequential management for maintaining 5S.

- Safety hazards in unorganised work place.

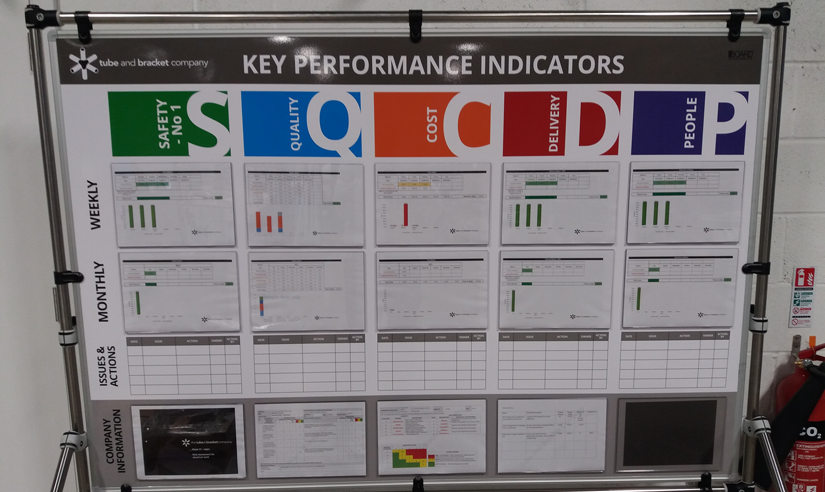

- Visual controls and it’s benefits

- 5S Audit system

- 5S Audit by team in shop floor/office.

- Brain storming for practical implementation.

Benefits:

- Clean work place.

- Easiness to employees.

- Forms a solid foundation upon which to build continuous improvement.

- Elimination of wastes.

- Smooth flow of process.

- High employee morale

- Employees gain a sense of ownership, involvement & responsibility

- Reduction in inventory

- Visual control improves work place management.

- Improved workplace organization

- Greater customer satisfaction.

- Builds good reputation of company.

- Higher efficiencies, more output per man hour.

- Best use of space.

- Reduced employee fatigue.

- Good ergonomics

Why to Choose Us

- Having experience of 500+ Corporate clients

- Have done 100+ implementations

- Trained more than 5000+ participants

- Highly industry experienced corporate trainer having experience with MNC’s

- Highly rated training programs

- Lowest cost

our partner