Lean Management

What is Lean Thinking?

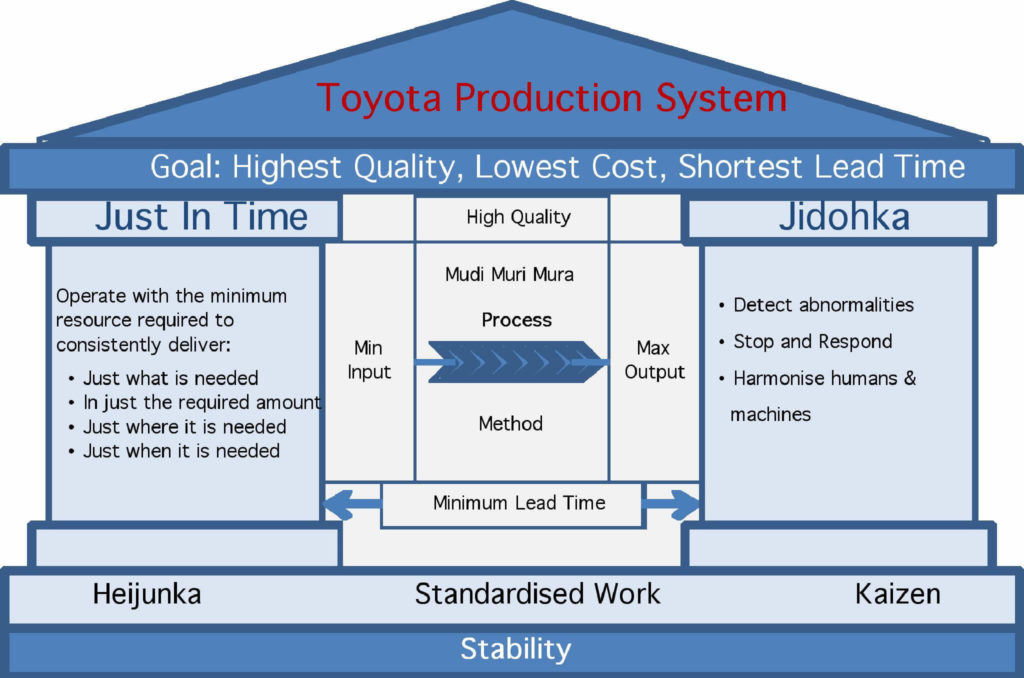

- Lean concept was developed by Taiichi Ohno (1912-1990) of Toyota Japan.

- Lean philosophy is based on the Toyota Production System (TPS), and other Japanese management practices.

- Replacing complexity with simplicity.

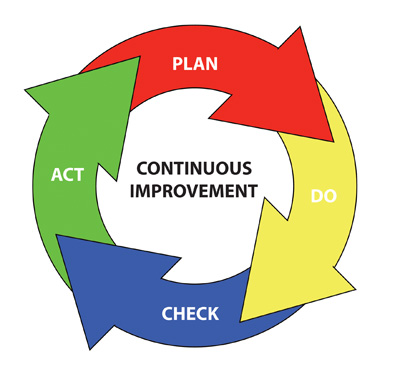

- Lean is a philosophy, a way of thinking, a process of continuous improvement.

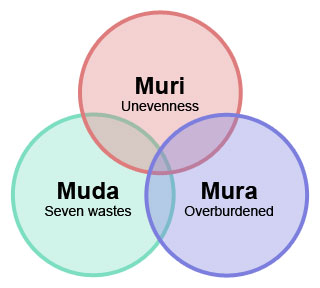

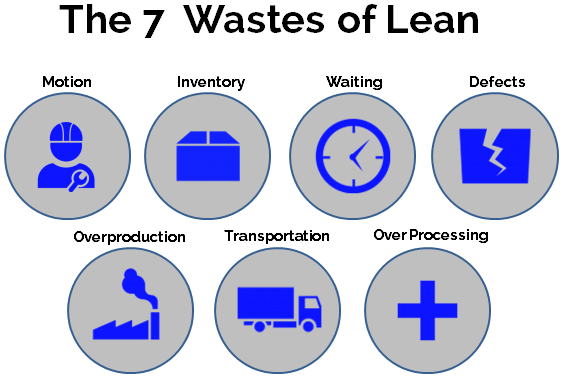

- Focuses on eliminating waste (or Muda) , that is anything that adds cost, consumes resources without adding value from the customer’s perspective, according to research conducted more than 60% of production activities in a typical manufacturing operation are waste – they add no value at all for the customer.

- Lean is all about doing more with less time, less inventory, less space, less people & less money.

- Through elimination of waste, processes become efficient, lead time between customer order and delivery gets shortened.

Topics Covered: Lean Management

- Lean fundamentals and philosophy

- Lean thinking, tools & goals

- Value added and non value added activities

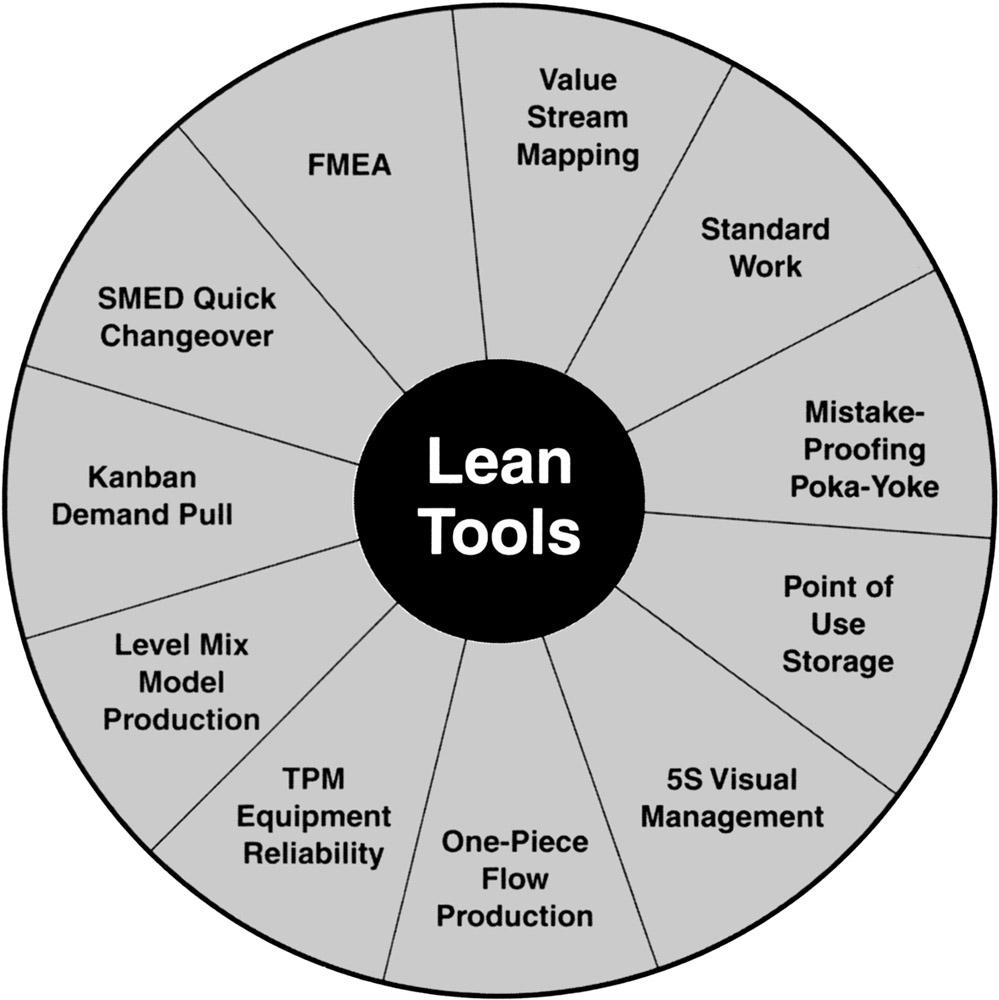

- Tools of lean

- Continuous improvement & PDCA

- 8 type of wastes

- Identification of 8 types of wastes.

- Cause of wastes

- Toyota production system

- Jidoka.

- Poka yoke.

- Andon.

- Kanban

- VSM.

- Push vs pull system.

- Muri,Mura & Muda.

- Heijunka.

- Cellular layout.

- SMED.

- JIT.

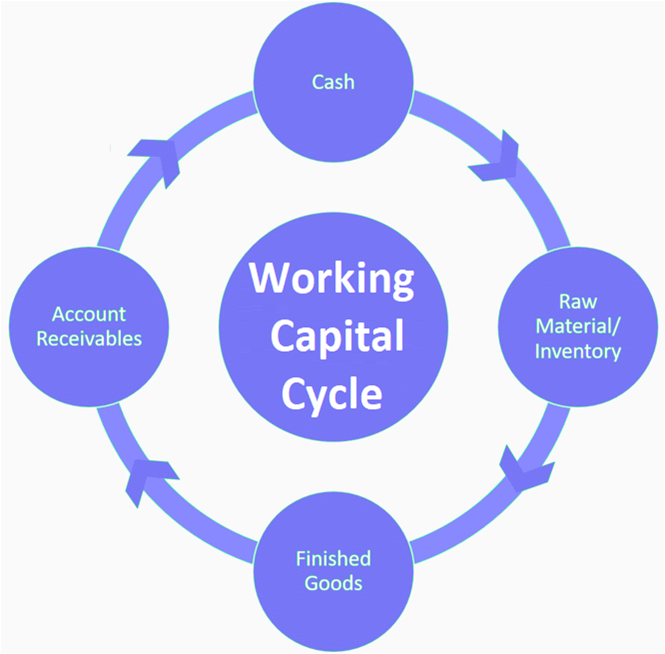

- Inventory management and control

- Quality management

- 5S (Organised work place)

- Visual controls.

- Kaizen

- Continuous improvement in SQDCME

Benefits of Implementation of Lean management:

- Forms a solid foundation upon which to build continuous improvement.

- Drive organization ahead by creating Continuous Improvement culture

- Safe work culture.

- Improved employee participation ,morale & involvement

- Employees gain a sense of ownership, involvement & responsibility.

- Good ergonomics, reduced employee fatigue.

- Ease to manage work place.

- Visual control improves work place management.

- Reduction in lead time (cycle time).

- Increase in productivity.

- Reduction in inventory.

- Improvement in quality, fewer defects and rework.

- Improved space utilization.

- Clean work place.

- Improved workplace organization.

- Greater gross margin & lower costs.

- Good relations with suppliers.

- Fewer machine and process breakdowns.

- Higher efficiencies, more output per man hour.

- Greater customer satisfaction.

- Greater flexibility –ability to handle more product variety

- Integrated supply chain

- Simplified & stable scheduling and control activities

- Elimination of wastes.

- Smooth flow of process.

- Greater gross margin & lower costs

- Good relations with suppliers

- Increase branding to customers.

our partner